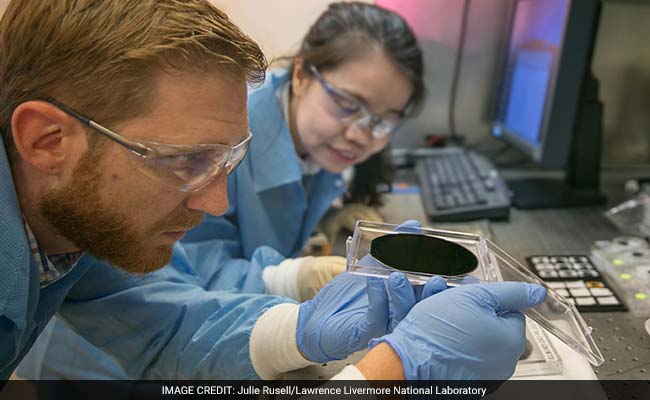

Scientists in a Livermore lab fabricated flexible polymeric membranes with aligned carbon nanotube.

High breathability is a critical requirement for protective clothing to prevent heat-stress and exhaustion when military personnel are engaged in missions in contaminated environments.

Scientists from the Lawrence Livermore National Laboratory (LLNL) fabricated flexible polymeric membranes with aligned carbon nanotube (CNT) channels as moisture conductive pores.

The size of these pores – less than 5 nanometres (nm) – is 5,000 times smaller than the width of a human hair.

To provide high breathability, the new composite material takes advantage of the unique transport properties of carbon nanotube pores.

By quantifying the membrane permeability to water vapour, the team found for the first time that, when a concentration gradient is used as a driving force, CNT nanochannels can sustain gas-transport rates exceeding that of a well-known diffusion theory by more than one order of magnitude.

These membranes also provide protection from biological agents due to their very small pore size.

Biological threats like bacteria or viruses are much larger and typically more than 10 nm in size. Performed tests demonstrated that the CNT membranes repelled dengue virus from aqueous solutions during filtration tests.

This confirms that LLNL-developed CNT membranes provide effective protection from biological threats by size exclusion rather than by merely preventing wetting.

The results show that CNT pores combine high breathability and bio-protection in a single functional material.

However, chemical agents are much smaller in size and require the membrane pores to react to block the threat.

To encode the membrane with a smart and dynamic response to small chemical hazards, researchers are surface modifying these prototype carbon nanotube membranes with chemical-threat-responsive functional groups.

These functional groups will sense and block the threat like gatekeepers on the pore entrance.

A second response scheme also is in development – similar to how living skin peels off when challenged with dangerous external factors. The fabric will exfoliate upon reaction with the chemical agent.

“The material will be like a smart second skin that responds to the environment,” said Kuang Jen Wu, leader of LLNL’s Biosecurity and Biosciences Group.

“In this way, the fabric will be able to block chemical agents such as sulphur mustard (blister agent), GD and VX nerve agents, toxins such as staphylococcal enterotoxin and biological spores such as anthrax,” Jen Wu said.

The research appears in the journal Advanced Materials.

(This story has not been edited by NDTV staff and is auto-generated from a syndicated feed.)